Walk into almost any shop floor, warehouse, or plant in Sacramento and you’ll hear it before you see it. The hum of machines. Conveyor belts moving. Lights buzzing overhead. Forklifts zipping by. All of it runs on one thing, electricity.

Here’s the problem: those systems don’t just “run.” They need care. And when they’re ignored, they fail.

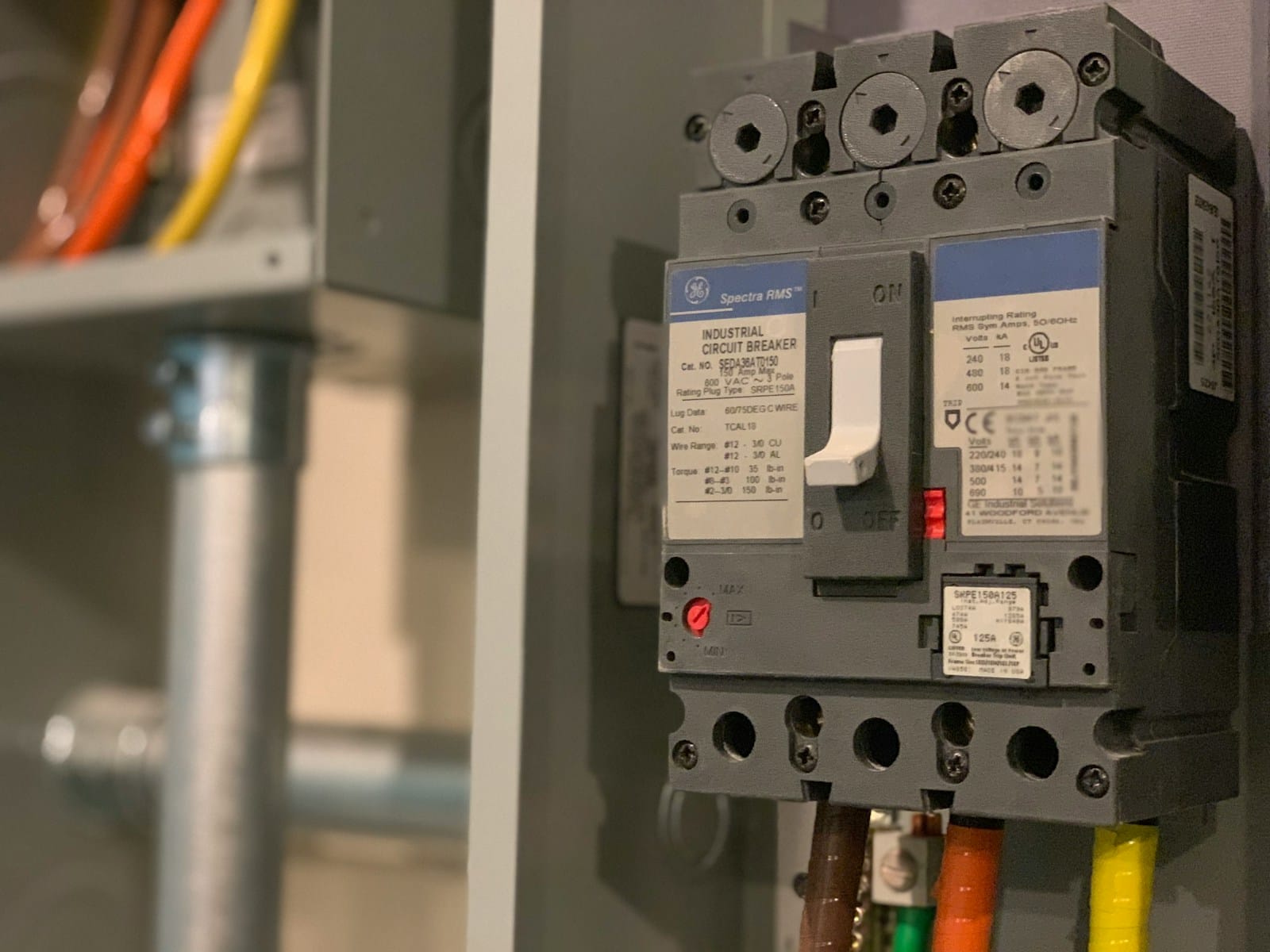

We’ve worked long enough in this trade to know, industrial electrical maintenance isn’t optional. It’s the difference between a business that hums along and one that loses a week of production over a tripped breaker or burned-out motor.

Table of Contents

Sacramento’s Workhorses Run on Electricity

Sacramento isn’t just politics downtown. Head toward Power Inn Road, out by the warehouses, or along Highway 50 toward Rancho Cordova, you’ll see distribution centers, manufacturers, food processors, aerospace shops. Every single one runs heavy electrical systems.

And here’s the thing: Sacramento’s environment doesn’t play nice.

- Summer heat – When it’s 105° in August, panels overheat, breakers cook, motors strain.

- Winter rain – Moisture creeps in where it shouldn’t. Rust, shorts, corrosion.

- Power surges – Between SMUD and PG&E service zones, flickers aren’t rare. That little “blip” you see at home? On an industrial line, it can knock a system out.

If you ask me, this is why local businesses can’t skip regular industrial electrical checks. The climate alone demands it.

Why an Industrial Electrician Isn’t Just an Electrician

A lot of people assume electrical work is electrical work. Residential, commercial, industrial, it’s all wires, right? Not even close.

- Residential: outlets, lights, panels.

- Commercial: offices, restaurants, HVAC tie-ins.

- Industrial: switchgear, high-voltage panels, PLCs, massive motors, generators.

Industrial work is a different. A short in your house might trip a breaker and kill your Wi-Fi. A short in a plant? It can stop an entire production line and cost tens of thousands in a single afternoon.

What Pros Bring to the Table

Safety, First and Always

Industrial systems aren’t forgiving. One mistake and you’re dealing with arc flashes, fire, or serious injury. Certified electricians follow OSHA and NFPA standards because the stakes are that high.

Preventive Eyes

From what I’ve seen, most big failures start small. A loose connection. A motor running a little hot. A breaker that trips once and then resets. Pros catch those before they spiral.

Tools You Don’t Own

Thermal cameras. Load testers. Specialized meters. The gear we bring out isn’t sitting in the back of a maintenance closet. It’s built for finding hidden problems before they explode.

Local Story: The Food Distributor Breakdown

A few summers ago, a food distribution center in South Sacramento called us in a panic. Their refrigeration units had all gone down, middle of July, 100+ degrees outside.

The culprit? An old breaker panel no one had touched in years. One overheated breaker tripped, and because the system wasn’t balanced properly, it cascaded. Half the plant went dark.

By the time we stabilized everything, they’d already lost thousands in spoiled product. The kicker? A basic maintenance check would’ve caught it months before. That job’s always stuck with me.

Services Sacramento Businesses Actually Need

Not every plant or warehouse runs the same systems, but here’s what keeps showing up on jobs around Sacramento, Elk Grove, Roseville, and Folsom:

- Infrared inspections – find hot spots before they turn into fires

- Panel and breaker testing – confirm systems can handle the load

- Motor and drive servicing – conveyors and pumps live or die by these

- Backup generator care – outages aren’t rare; generators need regular runs

- Wiring inspections – Sacramento’s older plants often hide brittle insulation

- Lighting upgrades – not just for efficiency, but to keep up with California energy codes

Truth is, these aren’t “extras.” They’re the backbone of keeping facilities online.

What Skipping Maintenance Really Costs

I’ve had plenty of business owners tell me maintenance feels expensive. Let’s run the numbers:

| Type | Ballpark Cost | What You’re Really Paying For |

|---|---|---|

| Preventive Maintenance | $500–$2,000+ per visit | Controlled cost, scheduled downtime |

| Emergency Repair | $5,000–$20,000+ | Chaos, halted production, lost revenue |

| Equipment Replacement | $20,000–$100,000+ | Weeks of downtime, capital outlay |

Ask yourself: would you rather plan for a $1,000 service call or get blindsided with a $30,000 repair bill?

Different Cities, Different Problems

Sacramento isn’t alone. We’ve worked in Elk Grove, Rancho Cordova, and Roseville too. Each area has quirks.

- Elk Grove: lots of new warehouses with huge demand. The systems are newer, but overloaded.

- Roseville: older industrial sites. Outdated wiring everywhere.

- Rancho Cordova: aerospace and tech shops with sensitive gear. Voltage swings wreak havoc here.

- Folsom: mix of small manufacturers and light industrial. Efficiency upgrades save them the most.

Wherever the job, the goal’s the same: keep businesses powered, safe, and compliant.

When to Pick Up the Phone

You don’t need to be an electrician to spot warning signs. Call a pro if you notice:

- Breakers tripping more than once in a while

- Motors running hotter than normal

- Lights flickering across the facility

- Strange smells around panels

- Equipment shutting down unexpectedly

Dangerous. Expensive. Preventable.

Compliance in Sacramento

California doesn’t go easy on businesses. Between Cal/OSHA and local codes, you’re expected to keep your systems up to spec. Skip maintenance, and you’re not just risking equipment, you’re risking fines.

In my experience, the businesses that stay on top of industrial electrical maintenance never worry about inspections. The ones that ignore it? They end up scrambling after a citation.

Bottom Line

Industrial electrical systems are the lifeblood of Sacramento’s industries. They don’t forgive neglect.

I’ve seen businesses thrive because they made maintenance a priority. I’ve also seen businesses grind to a halt over problems that could’ve been solved in a two-hour service call.

If you run a facility in Sacramento or nearby, Elk Grove, Rancho Cordova, Roseville, Folsom, don’t leave it to chance. Call Old Town Electric. We’re local, we know the codes, and we’ve kept Sacramento’s businesses running for years.

Because when it comes to industrial electrical systems, you don’t get do-overs.