Conduit selection might not seem like a high-stakes decision. But it is. It affects long-term safety, code compliance, cost, and, if you’re not careful, whether or not your project passes inspection.

If you’re pulling wires through walls, burying feeders to an outbuilding, or upgrading service panels, you’ve likely narrowed it down to two materials: PVC and metal.

They both have clear advantages. But they’re not interchangeable.

Table of Contents

Why Conduit Type Actually Matters

Electrical conduit serves one purpose: protect the wiring. But how it does that varies depending on material.

- PVC conduit resists corrosion and moisture.

- Metal conduit resists heat, impact, and fire.

When done right, either one can provide years of reliable protection. But picking the wrong one for the environment? That can lead to callbacks, failures, or worse.

PVC Conduit: Lightweight, Affordable, and Corrosion-Resistant

PVC (polyvinyl chloride) conduit is commonly used outdoors and underground. It’s flexible in how it’s used, and simple to install.

“If I’m trenching out to a detached garage, I’m using Schedule 40 PVC every time. It’s light, fast to cut, and won’t rust on me,” says Adrian D., a Sacramento-based electrician with over a decade of field experience.

Where PVC Performs Well

- Underground feeder lines

- Outdoor service runs

- Concrete slabs

- Wet locations or coastal regions

Strengths

- Non-corrosive and watertight (when glued properly)

- Lower cost than metal options

- Doesn’t require conduit grounding

- Simple to cut and assemble with basic tools

Limitations

- Not fire-rated for indoor use in most jurisdictions

- Weak structural integrity over long horizontal spans

- Softens in heat, becomes brittle in freezing temperatures

Pro tip: Always use expansion couplings outdoors. PVC expands and contracts with temperature swings more than most people realize.

Metal Conduit: Durable, Fire-Safe, and Widely Code-Compliant

Metal conduit is stronger and more protective than PVC. It’s the go-to in commercial settings and many finished interior spaces.

You’ll see a few main types:

- EMT (Electrical Metallic Tubing) – lightweight, often used in residential and commercial interiors

- RMC (Rigid Metal Conduit) – thicker, threaded, highly protective

- FMC (Flexible Metal Conduit) – ideal around motors or for retrofits in tight spots

“In a finished basement or garage, I’ll always spec EMT. It looks cleaner, supports boxes, and it’s going to last longer in a high-use space,” notes Linda R., an electrical contractor in San Jose.

Where Metal Excels

- Indoor walls or ceilings

- Garages and mechanical rooms

- Commercial buildings

- Anywhere fire codes apply

Strengths

- Fire-resistant and non-combustible

- Excellent mechanical protection

- Often acts as grounding path (reduces wire count)

- Stands up to impact, rodents, and UV exposure

Limitations

- Higher material and labor cost

- Prone to corrosion if not treated or coated

- Requires bending tools and experienced installers

Watch out: EMT is not rated for burial. If you’re going underground with metal, use RMC or IMC, and use anti-corrosion treatment at joints.

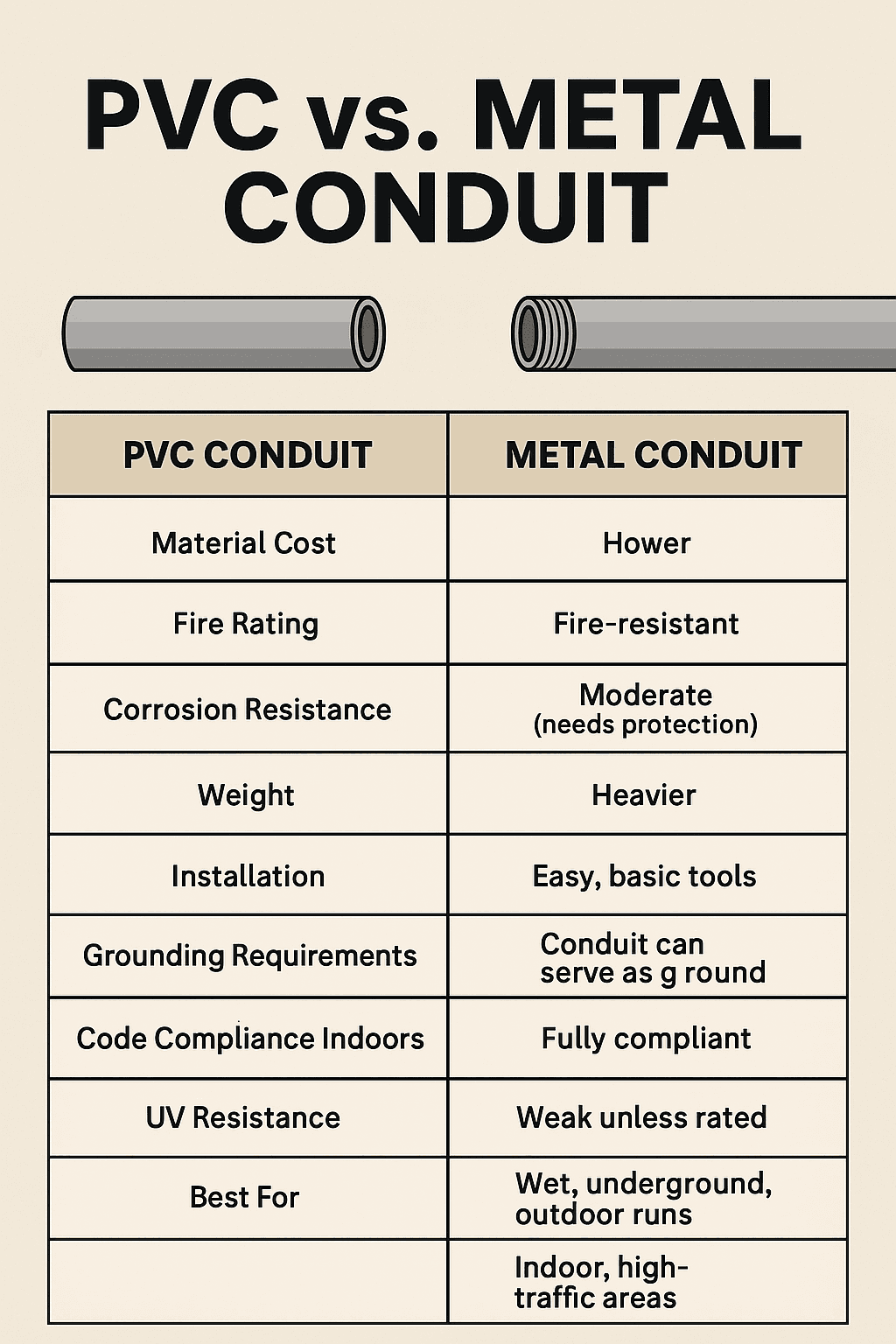

Comparison Table: PVC vs. Metal Conduit

| Feature | PVC Conduit | Metal Conduit (EMT/RMC) |

|---|---|---|

| Material Cost | Lower | Higher |

| Fire Rating | Not fire-rated | Fire-resistant |

| Corrosion Resistance | Excellent | Moderate (needs protection) |

| Weight | Lightweight | Heavier |

| Installation | Easy, basic tools | Requires bender + hardware |

| Grounding Requirements | Needs ground wire | Conduit can serve as ground |

| Code Compliance Indoors | Limited | Fully compliant |

| UV Resistance | Weak unless rated | Strong |

| Best For | Wet, underground, outdoor runs | Indoor, high-traffic areas |

What Local Code Might Require

Each region interprets NEC (National Electrical Code) a little differently.

- In Sacramento County, PVC is allowed outdoors and underground, but EMT is required inside most dwellings.

- In San Francisco, commercial spaces typically require metal conduit throughout.

- Coastal cities? PVC wins due to rust issues, unless you’re using stainless or coated metal.

Quick reminder: always double-check with the AHJ (Authority Having Jurisdiction) before finalizing materials. Inspectors may interpret NEC rules differently.

When You Should Use Each Type

Here’s a real-world breakdown:

Use PVC When:

- Burying conduit in soil or concrete

- Running wiring to exterior buildings

- Working in wet, corrosive, or salty environments

- Trying to stay within a tight materials budget

Use Metal When:

- Installing wiring inside finished spaces

- Fire protection is required by code

- The conduit is subject to physical damage

- You need to mount junction boxes or lighting directly to conduit

Mixed Installation?

No problem. Many pros run PVC underground, then switch to EMT or RMC above ground using rated transition fittings. It meets code, cuts costs, and gets the job done right.

Installer’s Take: The Long-Term View

“You save on labor with PVC, but you might pay more in callbacks if it sags or cracks. With EMT, the upfront cost is higher, but it rarely gives you problems five or ten years down the line,” says Raul M., a foreman with 18 years in the trade.

Every job is different. Sometimes cost drives the decision. Other times, it’s the inspector. In many cases, it comes down to the install environment.

If you’re not sure, ask yourself:

- Will this area be exposed to heat or water?

- Is there risk of physical impact?

- Will the conduit be visible, hidden, or buried?

- Is the project residential or commercial?

- Will this pass inspection?

Final Thoughts

The choice between PVC and metal conduit isn’t just a technical call, it’s a strategic one. Done right, it protects your wiring for decades. Done wrong, it causes headaches, failures, and failed inspections.

Use PVC for moisture-prone, underground, and outdoor installs.

Use metal when you need strength, code compliance, or fire safety indoors.

And if you’re in California, don’t guess. Talk to a licensed local electrician who understands both the materials, and the inspectors.

Need Expert Help?

Old Town Electric has helped homeowners and contractors across Northern California make smart, code-compliant conduit choices for over 20 years. From small residential installs to complex commercial rewires, our team gets it right, first time, every time.

Planning a project? Let’s talk.